the best professional titanium clad copper bus bars manufacturer and expert.

is one of the professional famous manufactory specialized in producing the various titanium metal composite materials products, such as titanium clad copper bus bar, zirconium clad copper rod, stainless steel clad copper anode, three layers metal composite bars, and composite silk material series products. Such conductive metal bars, platoons, generatrix or silk material, which outside layer is compound metal (titanium, zirconium, nickel, stainless steel), ensure its superior conductivity and strong surface corrosion resistance. So they are widely used in the condition of strong corrosion to conductive body, such as electro-chemical, electroplating, electrolysis, hydrometallurgy, PCB, electric chemical industry, water treatment, ocean engineering, etc.

With advanced explosion-rolling process, we provide the first rate non-ferrous metal composites, mainly titanium clad copper and also including zirconium clad copper, 316L steel clad copper, titanium clad 316L steel plates, bars, tubes, composite wire, and multi-layer clad composites, etc. The clad metal products could be up to four individual layers of metal or alloys. At minimum, there is a core and an outer layer; each layer thickness could be optimized to your needs.

Elegant Group has more than ten sets of CNC lathes, precision punching and thread processing machinery, to produce the titanium fasteners and machining parts. Titanium fastener production has two methods: mechanisms for processing class and precision molds upsetting extrusion molding class, according to the different needs of customers. Mechanisms for processing class with good appearance are used for high-end sports equipment industry, instruments, and equipment. High upsetting extrusion molding class with high strength and low cost, are used chemical, industrial equipment. Elegant Group has a strong mechanical processing capacity to produce various heterosexual titanium fasteners, non-standard titanium machining parts, titanium and other parts according to customer samples or drawings.

Processed products including non-ferrous metal, mainly titanium fasteners, screws, nuts, flanges and bends; Titanium and titanium alloy bars, rods, tubes, pipes, plates, sheets, wires, coils, foils, and sections with high machining precision; Various kinds of equipment made of titanium, such as titanium heat exchanger, titanium tray, and titanium anodes.

Titanium clad copper bars and other non-ferrous metals clad composite materials.

Titanium clad copper bars have been made by that a copper bar is clad in a certain thickness of titanium level, it mainly uses as a conductor under more corrosive work conditions. It is often used as a stand in plating, electrolysis, hydrometallurgy processes, because it has not only the original conductive property of the copper bar, but also protecting the copper bar from corrode by titanium level, and can greatly lower pollution of electrolyte and electroplate.

But, if you request that the material has this function above, then you must be sure that there are much stronger combination strength and much higher pasting rate between the copper bars and the titanium level, this can not be met by traditional mechanical combination methods. So in order to overcome it, our company, with advanced explosion-rolling process, has successfully produced titanium clad copper bars with sheared strength ≥ 130 Mpa, compact rate ≥ 98%, we can also supply the various specification of round, square, flat bars material, the longest length of the bars can reach above 10 meters and we can weld different shape material together in according to the clients request. We could also make nickel clad bars, stainless steel clad copper bars, and zirconium clad copper bars series products through the same process technology.

Unsurpassed advantage performance of Titanium Clad Copper bus bar anode:

(1) Good Shear and tensile strength: The shear and tensile strength is tested and guaranteed in accordance with GB, ASTM, and JIS.

(2) Perfect Elongation and Ductility: Elongation and Ductility of cladding metal is guaranteed in face bend (=cladding metal in tension), and the ductility of base metal is guaranteed in reverse bend (=cladding metal in compression).

(3) Good Hardness: The bonded interface is slightly hardened after explosion bonding. The interface can be softened by heat treatment to an original level. There exists no difficulty in bending and drawing works

(4) Excellent electrical conductivity: explosions-rolling process of the production make titanium and copper composite close completely with no delamination and therefore has good electrical conductivity, the composite strength of 135Mpa, and micro-resistance for 7.77 × 10-6Ω

(5). Fantastic Corrosion Resistance: Explosion bonding, a clad processing, guarantees excellent corrosion resistance of clad materials.

(6) Great weldability for connecting, capping and joining

(7) High reliability; High conductivity; Biocompatibility; Weld ability; Cost effective.

Strict Products Inspections to ensue us to provide 100% Titanium clad copper bars and other non-ferrous metals clad composite materials.

Our products 100% Ultrasound inspect and visual Test. Microstructure inspection, physical inspection, chemical composition analysis and other special test and inspection are carried out in independent labs.

HPF titanium and titanium alloy clad composites is the leader in the titanium industry. If you know the type clad composites you are interested in, you are kind to select it. When you are not sure which one you need, or would like to know more information, feel free to call us directly to discuss your particular requirement and we can help you decide which one is the best one.

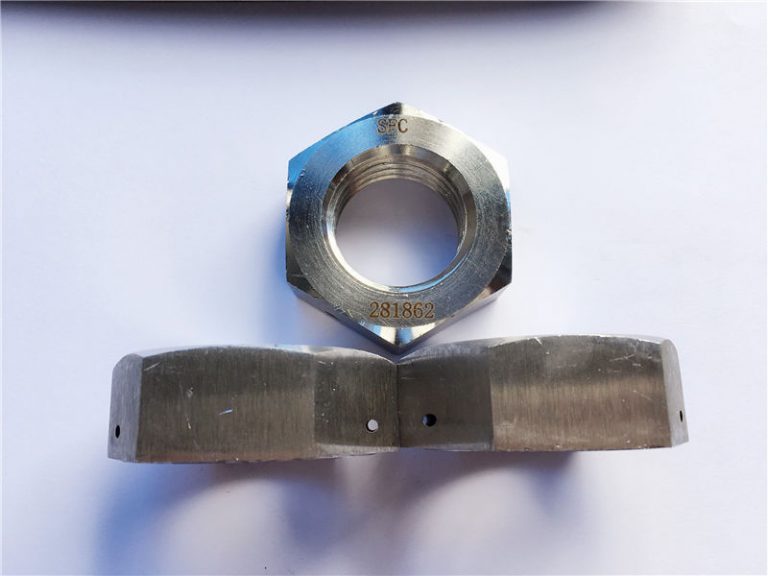

Titanium Fasteners specifications:

tem Name | Titanium Fastener |

| Item type | Slotted cylindrical head / Socket conical hex-head / Socket cylindrical hex-head /Slotted round head cap /Recessed cylindrical round hex-head /Slotted countersunk flat head/ Slotted countersunk head cap /Slotted wide round head /Hex-head screws with washer /Twelve point head /Slotted cylindrical head self-threading /Slotted flat countersunk head self-threading /Hexagon socket headless /Slotted headless |

| Materyal | Pure Titanium and Titanium Alloy |

| Material grade | Gr1,Gr2,Gr3,Gr4,Gr5(Ti-6AL-4V),Gr7,Gr9,Gr12, etc. |

| Pamantayan | GB,DIN,IFI,UNC,UNF,JIS,BS,BSW,ISO |

| DIN912,DIN913,DIN914,DIN915,DIN916,DIN931,DIN933,DIN934,DIN84,DIN963,DIN125,DIN 127,DIN433,DIN7991,7984,6921,6923,ISO 7380,JIS,BS etc. | |

| Pagtutukoy | Screw/bolt: M2~M64,Length 6~300mm |

| Nut: M2~M64 | |

| Washer: M2~M64 | |

| Supply non-standard and special size according to customer's requirement | |

| Paggamot sa Ibabaw | Polishing, anodizing, black oxide |

| Kulay | Ti natural, gold, blue, Purple, green, etc. |

| Mga Tampok | light weight (4,5 kg/dm3), acid and alkali resistance, anti-corrosion, excellent mechanical strength, Low thermal expansion coefficient, High elasticity, Good mechanical resistance (specially in alloys), Non magnetic element |

| Aplikasyon | Equipment accessories: airplane, ship, bicycle, motorcycle, auto, medical, chemical, sports, etc. |

Titanium clad copper bus bar anode/ composite bar/ rod specifications: | ||||

| Section shape | Section size(mm) | cladding material | Substrate material | |

| layer thickness | materyal | |||

| square | Side length(10-40) | 1.0-2.5 | Ti, Zr, Ni, Stainless steel | T1,T2, TU1,TU2,AL, Stainless steel, etc |

| rectangle | Side length(20-160) side width(10-30) | 1.0-2.5 | ||

| drum | Side length (25,27,29,32,34)*14 | 1.0-2.5 | ||

| round | Dia (8-50) | 1.0-2.5 | ||

| wire material | Dia (2.0-8.0) | 1.0-2.5 | ||

| Application: | wet metallurgy, Electroplating, electrolysis , petroleum chemical industry, Electric chemical industry, Energy engineering, ocean engineering, Surface treatment, electrode manufacturing, electro-purification, caustic soda electrolysis, and aluminum anodizing,Machining field, Automobile field, Desalination of sea water, Textile printing and dyeing, Mobile phone component field, Electronic circuit board, PCB, print circuit makers and stee | |||